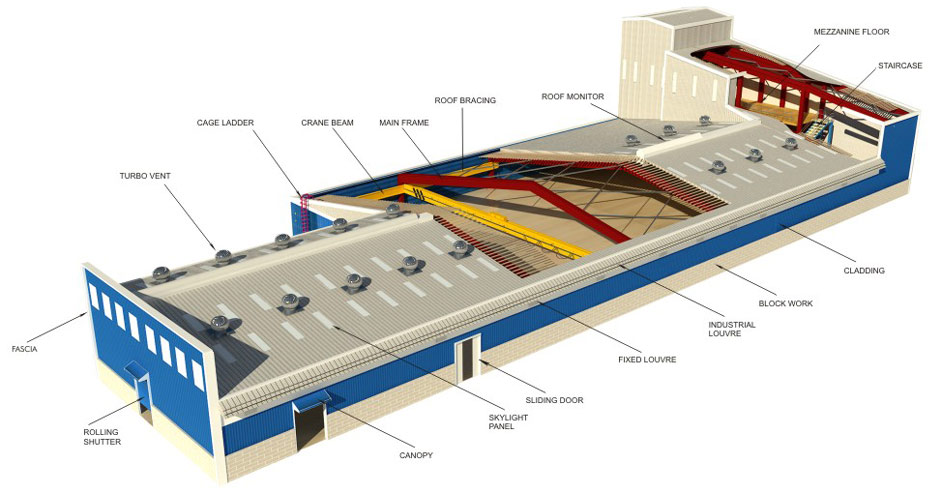

PRE-ENGINEERED BUILDING

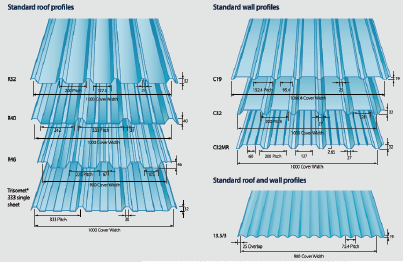

A pre-engineered building is a metal building that consists of light gauge metalstanding seam roof panels on steel purlins spanning between rigid frames with lightgauge metal wall cladding. It is a relatively flexible structure vs a conventional steel framed building.

PRIMARY FRAMING

Primary frames are designed in accordance with the steel construction manual published by American Institute of Steel Construction (AISC).Manufacturing dimensional tolerances are in accordance with the requirements of ‘Metal Building Manufactures Association’ (MBMA) of USA, “Low Rise Building Systems Manual”. Besides AISC and MBMA, we also design buildings with Indian Standards.Built-up sections are fabricated from hot rolled steel plates confirming to ASTM A 572M grade or equivalent with minimum yield strength of 345N/mm2 (50ksi). The most common primary framing systems are illustrated here. All structures shown are symmetrical about the ridgeline. Framing systems..